Description

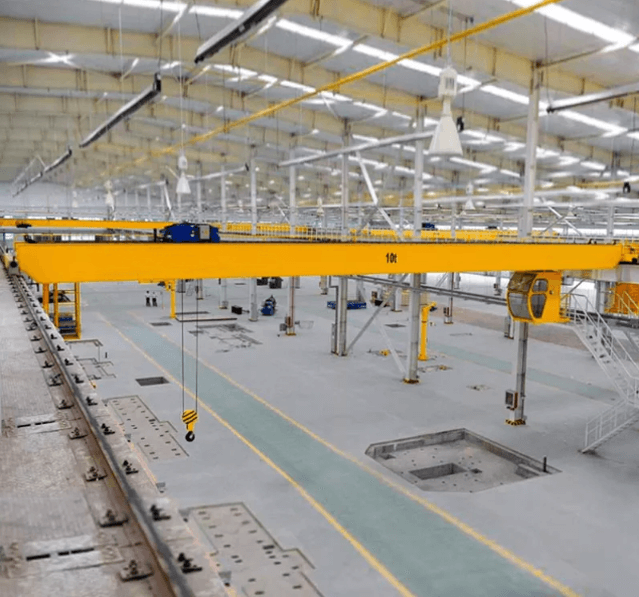

European double girder overhead travelling crane design, manufacture and inspection are carried out in accordance with FEM, DIN, IEC and other standards, compared with the original general QD type overhead travelling crane products, the dead weight is reduced by about 15-30%, the wheel pressure is reduced by about 10-35%, which can reduce the requirements of the crane on the plant structure and save the plant manufacturing costs.

The core components of the transmission mechanism reducer all use hardened gear surface, high-precision gear vice, coupled with the application of steel reels, forged wheels and frequency conversion speed control system, making the model crane a new generation of products with good economic and social benefits, suitable for machinery manufacturing, assembly, petrochemical, storage and logistics, power construction, paper making, railroad and other industries.

It can effectively increase the working space in existing facilities. The main components that constitute the European bridge crane include the main beam, end beam, lifting trolley, crane operating mechanism, electrical device and control system

- Bridge crane main girder

The main girder is constructed with H-shaped steel structure. Automatic welding is adopted and non-destructive testing is carried out on the main welded joints.

Off-rail box structure with high strength bolt connection to the end girder for easy transportation. Specialized processing equipment ensures the accuracy of the main end girder coupling and makes the crane run smoothly.

- End Girder

The end girders are connected to the two main girders by high strength bolts to ensure smooth movement. They are made of rectangular steel tubes or steel plates.

- European type electric hoist trolley

The Euro hoist trolley has a maximum lifting capacity of 80 tons. It provides accurate positioning, stable movement and efficient operation. It can be equipped with variable frequency hoist or double hoist according to customers’ needs.

- Crane travel mechanism

The large crane and trolley travel mechanism adopts SEW 3-in-1 motor and Schneider or ABB inverter, which provides fast and smooth movement.

- Control System

The double girder overhead crane is operated by wireless remote control or cabin control.

Reviews

There are no reviews yet.